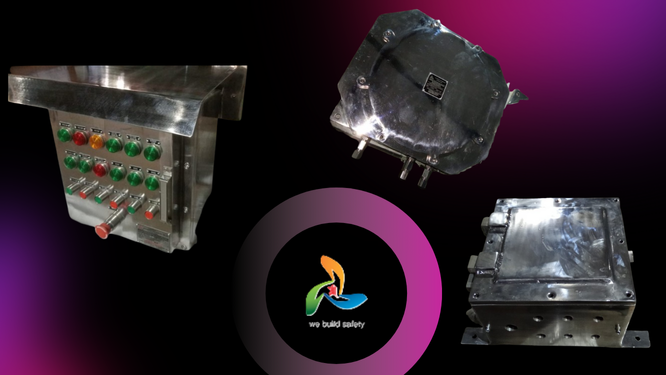

Stainless Steel Enclosures: The Durable Shield for Harsh Environments

- Shreeelectrical

In industrial, commercial, and outdoor applications, protecting sensitive electrical and electronic components is not just important—it's essential. That’s where stainless steel enclosures come into play. Designed to safeguard valuable equipment from moisture, dust, corrosion, and impact, these rugged enclosures are a reliable solution for the most demanding environments. Whether you operate in food processing, pharmaceuticals, marine operations, or outdoor energy systems, stainless steel enclosures offer unmatched durability and performance.

What Are Stainless Steel Enclosures?

A stainless steel enclosure is a protective housing made from corrosion-resistant steel alloys—primarily 304 or 316 stainless steel. These enclosures are engineered to protect electrical controls, instrumentation, junction boxes, and other sensitive devices from external hazards. What sets them apart from other materials is their resistance to rust, extreme temperatures, and harsh chemicals, making them suitable for a wide range of industries.

Types of Stainless Steel Used

- 304 Stainless Steel: Offers excellent corrosion resistance and is suitable for most indoor and general industrial applications.

- 316 Stainless Steel: Contains molybdenum for superior resistance to chemicals and saltwater—ideal for marine, chemical, and outdoor use.

Both grades are known for their strength, ease of cleaning, and long-term performance.

Common Applications

Stainless steel enclosures are trusted in numerous sectors due to their hygienic and robust properties:

- Food & Beverage: Easily cleaned and resistant to contamination, making them perfect for hygiene-sensitive environments.

- Pharmaceuticals: Ideal for sterile environments where cleanliness is regulated.

- Oil & Gas / Chemical Plants: Withstand corrosive atmospheres and extreme temperatures.

- Marine & Coastal Installations: Excellent for withstanding salt spray and moisture exposure.

- Outdoor Power Systems: Protect vital electrical systems from rain, dust, and UV exposure.

Protection Ratings

These enclosures often come with industry-standard ratings:

- NEMA 4X: Corrosion-resistant and water-tight; used outdoors and in wash-down areas.

- IP66: Dust-tight and protected against powerful water jets—ideal for rugged environments.

Understanding the rating ensures you choose the right enclosure for the job.

Benefits of Stainless Steel Enclosures

- Corrosion Resistance: Outperforms painted or plastic enclosures, especially in corrosive environments.

- Longevity: Withstands wear and tear for decades with minimal maintenance.

- Hygienic Design: Smooth, sealed surfaces prevent bacterial growth and are easy to sanitize.

- Weatherproof Protection: Ideal for both indoor and outdoor applications.

- Enhanced Safety: Reduces the risk of electrical hazards by providing a secure barrier.

Design Options

Stainless steel enclosures are available in a variety of designs:

- Wall-mounted or free-standing

- Hinged doors, lockable panels, or removable covers

- Vented, sealed, or climate-controlled

- Options for viewing windows, custom cutouts, or integrated cable management

Whether you're installing a small junction box or a full electrical control cabinet, there's a configuration to fit your needs.

Choosing the Right Enclosure

When selecting a stainless steel enclosure, consider the following:

- Environment: Will it be exposed to chemicals, salt, or high humidity?

- Size & Layout: What equipment does it need to house?

- Access Needs: How often will it be opened or serviced?

- Certifications: Look for UL, CSA, IEC, or CE certifications for safety and compliance.

A thorough needs assessment will help ensure long-term success and safety.

Conclusion

Shree Electrical & Engineering Co.’s Stainless steel enclosures provide the strength, resilience, and cleanliness required to protect mission-critical components in the harshest environments. Their versatility, longevity, and compliance with global standards make them an investment in safety, efficiency, and operational continuity. Whether you're upgrading an old system or designing a new installation, stainless steel enclosures are a smart, future-proof choice.